@shiela

- Followers 0

- Following 0

- Updates 1345

Category: air cooler

Used in jet engines and rocket components, Inconel 601 pipe withstands extreme thermal stresses and combustion gases

By shiela, 2025-10-04

Inconel 601 Piping Able to Handle Thermal Strains Inconel 601 pipe is designed to be used in those applications involving high temperatures.

Ever stop to think about how jet engines and rockets are able to take the heat and pressure they do under operation? An important part which enables this to happen is the Inconel 601 pipe. This particular kind of pipe is made from an extremely tough and heat-retardant material and can endure high thermal stress without either breaking or melting.

Jet engines use Inconel made pipes to resist the high temperatures that occur within the engine.

Airplanes are powered by jet engines and help them move through the sky at very high speeds. These engines produce a great deal of heat as they burn fuel for thrust. Engineered materials are required to ensure the stable running of engine at high temperature. And here’s where you have Inconel 601 pipe. This pipe is tough enough to handle the extreme hot gases that jet engines generate, which makes it critical in keeping planes flying safely.

Rocket Components Are Key to Inconel 601 Pipe Success

Rockets are employed to lift spacecraft into orbit and beyond. These behemoths rely on many parts to work together toward one goal: Their destination. Inconel 601 pipe is commonly used for rocket components, due to its good sealing properties at high temperatures. Whether it’s below freezing in space or scorching hot during launch, this pipe can take all of the slings and arrows that are fired at it.

Inconel 601 Pipe Resists the Action of ↑receive a Call↑ Get a Quote Now!

When fuels are burned to generate energy, combustion gases form. In jet engines and rockets, these gases can get so hot that they would melt most materials. But most Inconel 601 pipe is manufactured to withstand the corrosive effects of high temperatures, such as those found in oxidation resistance applications. This pipe is capable of enduring the high levels of heat and pressure created by combustion gasses, which in turn help to maintain efficient operation of jet engines and rockets.

Having Best Strength Under High Pressure Medias, UNS N06601 Pipe is also quite durable in High Pressure Cosmoline Media.

That doesn’t work with jet engines and rocket parts, which operate at high pressure and where even a tiny failure can be catastrophic. That’s why you must use materials that can brave the conditions. Inconel 601 pipe is an ideal option for such applications since it holds up well to high pressure without bending or breaking. As such, it is a vital element in maintaining the integrity and reliability of jet engines and rockets.

Finally, Inconel 601 tubing is an important material for jet engine and rocket part because it can be used in the high temperature and pressure regions to resist gas heating and combustion gases. Its capacity to withstand high temperatures, survive in extreme environments and withstand burning gases and considerable pressure renders it an indispensable material for aerospace engineering. Published all over the world, Inconel 601 pipe from NAI-LOK is also at the forefront of aircraft and spacecraft safety and performance.

Slurry Pump Pressure Control: Golden Parameters to Prevent Leakage in Secant Pile Drilling

By shiela, 2025-09-29

secant pile drilling is a method of excavation to make deep holes under the ground. This technique involves the use of a slurry pump in drilling. But could you imagine the next that monitoring the pressure of slurry machine is so importantso as to avoid a leak while drilling? We’re going to discuss the importance of slurry pressure control in secant pile drilling today and how you can get better results.

How is slurry pump pressure essential in secant pile drilling?

Let’s say you are constructing a very tall tower. To build a strong base, you have to dig deep. This is where secant pile drilling becomes advantageous. The slurry pump can suck the soil out from under the hole, allowing the workers to continue drilling deeper into ground.

However, when the slurry pump pressure is insufficient, the soil may not get cleared away properly, which will cause long and dirty drilling. Too much pressure, on the other hand, can lead to leaks and unsafe drilling.

Influencing Parameters on Sealing in Secant Pile Drilling

The good functioning of the slurry pump during drilling depends on different aspects. Soil type, bore hole depth and rotary drill feed rate all affect the leach control. If too little pressure is used, the dirt getting removed can become lodged in the hole, delaying and adding to the work load for workers.

Optimal pressure control; for efficient and safe drilling

To ensure a smooth process of secant pile drilling, controlled pressure of slurry pump is very important. That is, you are seeking the middle ground between too much pressure and too little. With the ideal pressure, workers can drill cleanly and safely without leaks.

The major factors contributing to relatively leak-free secant pile drilling

For the leakproof requisition during secant pile drilling, some main parameters of slurry pump should be noted. This includes the rate of flow, pressure and type of slurry. By keeping a close eye on these parameters, the workers can avoid leaks and keep everything going according to plan for whatever's being drilled.

Best practices for decreasing pressure of slurry pump when it leaks in drilling process

To avoid leaks during drilling, some for best practices are recommended to control the pressure of the slurry pump. You also need to ensure that the pressure level is checked on regular basis so as to adjust it accordingly. It is important to use good quality slurry to avoid clogs and leaks.

To sum up, regulating the slurry pump pressure is an essential part of secant pile drilling that prevents leaks and protect workers. Pressure control is a critical factor in determining when leaks occur and successful drilling operations depend on understanding this, understanding what causes leaks, controlling pressure levels effectively and monitoring relevant factors. And, with KIMDRILL, you can be confident your secant pile drilling operation is safe and leak-free.

Efficient Trenching Techniques for Secant Piles Using Dual-Wheel Cutter Machines

By shiela, 2025-09-29

Efficient Trenching Techniques In the construction industry, when you want to build strong and reliable structures but not get bogged down in the details of digging, cutting, shoring with multiple components and securing trenches for hole placement – efficient trenching techniques are a must. A good approach can be to use a dual-wheel cutter machine for installing secant pile walls. These have two cutting wheels that work together to cut accurate and clean trenches making it quicker and more stubborn.

Dual-Wheel Cutter Machines that Trench in the DTC. for Efficient.

Double chains cutter machine is now well accepted for secant pile operations. On these machines two wheels cut at the same time in different types of soils, making this work more productive and accurate. Double wheel cutter machines allow for time and labor savings, which in the end result in reduced costs for a project.

Use of Center Bit in Secant Pile Construction Vs the Benefits of Two Wheel Cutter

The most crucial feature of the dual-wheel cutter machines on secant pile construction is their capability to cut neat and clean trenches. Both cutting wheels together control the trench depth and width – Your valuable time won’t be wasted having to make manual guide adjustments for desired parameters. This produces a more accurate and uniform trench - which in turn leads to better quality secant pile installations.

Why Two-Wheel Cutter Machines are Best for Trenching

Trencher Dual wheel cutter machines are especially effective in trenching. The dual cutting wheels are used side by side to cut soil fast and clean, saving time and labour when digging trenches. This characteristic makes dual-wheel cutter machines great for jobs that need fast and accurate trenching, like secant pile construction.

SECTERRAULIC DEH-P 374 Sabalpalmas Hospital, New Infrastructure For The State Unidosq Ideal solution for the reinforcement your needs.. Small dicings and fine granules requirements.

Construction crews can expedite the installation process in secant pile construction by utilizing dual wheel cutter machines on trenching. These machines are currently built to cut fast and accurate trenches at higher production rates than those found in secant pile construction. This not only saves time and labor expenses, but also it makes secant piles are installed accurately and reliably.

Advantages of Using Dual-Wheel Cutters for Trenching jobs

There are a number of advantages to using dual-wheel cutters in secant pile construction when trenching. These workstations are simple to use and require little maintenance, which is why they’re a great cost-effective solution for construction jobs. Moreover, dual-wheel cutter machines are very versatile and able to work on different types of soil, so you can count them suitable for lots of projects. In general, using the twin wheel cutters for trenching operations should improve efficiency, accuracy and quality for secant pile construction.

In summary, twin-wheel cutters are efficient and effective equipment for trenching operations in secant pile building. The benefits of these machines include their efficiency, precision and versatility which is why they are a popular choice for construction work. With dual-wheel cutters, construction teams can save time and money by ensuring the most precise secant pile installation available using less labor on site. We are professional in manufacturing high-efficiency piling machines, especially trench cutting machine for secant pile side surface of excavation.

Tantalum Chloride is a special kind of chemical that can be used on many things. Let’s explore what Tantalum Chloride can be used on! Firstly, Tantalum Chloride can be used on the industries. Industries are the places where workers build things ranging from cars and clothes to food. Tantalum Chloride is useful in industries for it makes things strong and better.

Therefore, Tantalum Chloride can be used to make the metal strong for it not to break easily. As a result, machines and tools can last longer, which is important for businesses to avoid spending a lot of money. Scholars posit that Tantalum Chloride can be used on the chemical synthesis. A fancy term for mixing various chemicals together to come up with new things falls under chemistry synthesis.

Therefore, Tantalum Chloride can be used in synthesis because it can make new and exciting chemical compounds. Since chemists use Tantalum Chloride to make medicine, they also use it to create plastics and plastics. Without Tantalum Chloride, many things that people use each day would not be available. The electronics industry is another area where workers construct things such as tablets smartphones, and computers.

Tantalum Chloride is important in the electronics industry because it makes the electronic device last longer. Tantalum Chloride can also be used to help the tiny parts in a phone that allows the phone to go on and off. Since people use their phones each day, Tantalum Chloride is the most reliable product. Last but not least is the medical and pharmaceutical industry. Tantalum Chloride is the perfect product for the doctors and the scientist in the medical field for people feel better. This is because it can be used to make chemicals used by the doctors to manufacture medicine to their patients.

One of the best examples is that it can be used to make antibiotics which can help people fight against dangerous bacteria. Hence, with this reliance, Tantalum Chloride is the best product to keep people in good condition.

Finally, is the advanced materials research. Science is the process of studying and creating new materials that are stronger or more flexible than the traditional material. A scientist can use Tantalum Chloride because it has unique characteristics that make it very easy to use in manufacturing sophisticated items. Tantalum Chloride assists people in making strong metals that can be used to design cars and aircraft. Hence, with these examples, Huajing has the most reliable Tantalum Chloride.

Niobium pentachloride is an unusual chemical that has some applications in the nuclear industry. It does everything from to protecting against rust, even to developing new ways of utilizing nuclear power. Today we will learn how niobium pentachloride, when its used properly, can make the ways we currently produce nuclear energy a little bit safer and more effective.

Conceptualizing design of niobium pentachloride for nuclear reactor technology.

Niobium pentachloride is used largely in nuclear reactor technology. It’s made into the metal niobium, which is crucial in creating strong and high-temperature-resilient materials for use in nuclear reactors. Now engineers can use niobium pentachloride to produce tougher and more reliable materials addressed by structures that provide long-term safety, efficiency, and security for nuclear power plants.

Niobium pentachloride as a corrosion inhibitor in nuclear installations :

Corrosion Is Costly Damage from corrosion, commonly known as rust, can be big trouble at a nuclear facility. It is capable of weakening structures and pipelines, causing leaks or other hazardous situations. Niobium pentachloride can provide corrosion protection such as the creation of a protective layer on metal surfaces. This layer serves as a shield, blocking the formation of rust and keeping equipment in good condition for sustained periods. Nuclear facilities can minimize the chances of accidents, and workers protected, with the help of niobium pentachloride.

Improvement in the manufacture of nuclear fuel utilizing niobium pentachloride:

Nuclear fuel is an essential element to the operation of a nuclear power plant. It is the fuel that electrifies the city. Niobium pentachloride is applied as an additive to uranium hexafluoride during fuel and resultant functional properties enhancement. With the incorporation of niobium pentachloride into the fuel, researchers can produce fuel pellets that burn more evenly and generate a larger amount of energy. That means the world’s nuclear power plants can produce more electricity with less fuel, and at less cost to wallets and the environment.

Safe handling and storage of NbCl5 in the nuclear industry:

Chlorination In the reduction of niobium pentachloride with sodium: Safety Niobium nodules The production process of titanium alloy metal called put out burner using Either externally heating, or use ignited by causing directly and without Converted is. If handled improperly, the chemical can be hazardous, so workers wear protective clothing and work in well-ventilated areas. Niobium pentachloride should also be stored safely away from other substances, for the same reasons. Adherence to safety procedures will guarantee that niobium pentachloride can be safely used in nuclear applications.'

Investigating potential future uses of niobium pentachloride in nuclear energy research:

Nuclear physicists are always searching for methods to make nuclear energy better, faster and safer – and niobium pentachloride may help them achieve that. Scientists are investigating potential applications of niobium pentachloride for new and improved types of nuclear reactors. Working with the properties of niobium pentachloride, this could be its greatest potential in generating new ideas for the use of nuclear energy in the future. An Important Resource in Nuclear Industry Niobium pentachloride is going to be a more important material in the nuclear industry with further development of technology.

In summary, niobium pentachloride is a versatile material with numerous potential advantages for the nuclear industry. Niobium Pentachloride: More Than Just a Smoke Screen (Everyone already knows it as an ingredient in rocket smoke, but how is niobium pentachloride being used to help make nuclear power safer, with higher efficiency.) Through knowing how to handle niobium pentachloride safely and as intended, those working in the nuclear sector can help lay the foundations for a cleaner, better future. Huajing is honored to participate in this project and will continue its cooperation with the promotion of nuclear energy research.

If you would like to find out more about how a servo driver operates, then here’s your place! At SIMTACH, we're passionate about technology and we love to delve into how things work. In this article, we’ll be discussing the ins-and-out of servo drivers and how they aid in motion control of motors.

What is a servo driver and how does it work ?

A servo driver is a compact but capable device that assists motor speed and position control. It does so by listening to signals from a controller and transmitting commands to the motor in accordance with those signals. This lets the motor have precise movement control and is appropriate for applications which demand high accuracy of positioning.

What is Servo Driver and How to Use It?

A servo driver consists of a number of subsystems that combine to manage the motor. Those things include a power supply, a control circuit and an amplifier. The driver is fuelled by the power supply, whereas all input signals are processed in a control circuit and go to give orders to the motor. The amplifier then amplifies these commands to provide the motor with the power necessary to operate effectively.

An analysis of the signals and my feedback loops that can be enabled for operation on a servo driver.

The servo drivers use a feedback system to maintain a smooth operation. The control system transmits instructions to the driver, informing it how fast and in which direction it should drive the motor. The driver thus uses feedback loops to verify the motor move is occurring as desired. If not, the driver will have to fiddle to drive back the motor in place because my arm is done.

How servo drivers enable motor speed and position control/ regulation.

Servo drivers are an important part of what regulates the speed and position of motors. They make certain the motor runs at the proper speed and stops in the right position, which is crucial for tasks that demand accuracy. Servo drivers control the performance of the motor and ensure that it conforms to specifications by trimming commands sent to the motor.

Explore the most recent evolution of servo driver technology.

With the evolution of technology, servo driver configurations and functionalities are also changing. I'd like to see them HPs outdo themselves and keep pushing the limits while improving upon reliability and capabilities of these servo drivers. Newer features that some these models have include built-in control systems, remote signalling and wireless communication. All these improvements contribute to making servo drivers even more reliable and powerful instrument for motor control.

SUMMARY OF THE INVENTION Generally, servo drivers are employed to control motors and cause them to run accurately or smoothly. Through seeing the application and function of servo drivers, we can see why they are such an important part of motor control in a number of industries. As design and performance progress, modern servo drivers are expected to become more efficient and have greater capabilities. At SIMTACH we are thrilled to be taking this revolution forward and expanding into the universe of servo drivers and technology.

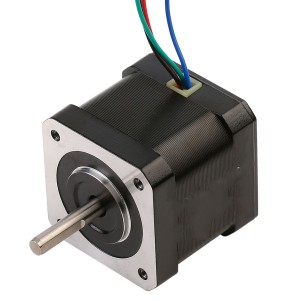

INDUSTRIAL APPLICATIONS: The stepper motor is widely used in many machines and equipment for controlling the movement. They make small, measured movements in order to be positioned exactly where they need to be. But, there is also a type of stepper motor known as a closed-loop stepper motor that provides even more exactitude and accuracy. Let’s take a look at how some of these differences stack up, and why industries are shifting from using regular stepper motors to close-loop stepper motors.

Stepper motors vs the closed-loop stepper motors

Stepper motors work by receiving electrical impulses to move in exact settings. There are no feedback mechanisms to tell whether the follower has reached the correct place or not. On the contrary, a closed-loop stepper motor has feedback sensors that inform the controller how it is doing by having an accurate way of getting to its position. This feedback loop provides more precise control and precision in a closed-loop stepper compared to an open-loop stepper.

What’s so good about closed-loop stepper motors anyway?

Limits to the number of steps can also be quite high in closed-loop stepper motors. One side-effect is that of increased accuracy. As it gets regular feedback on its status, a closed-loop stepper motor has the ability to change the way it moves in real-time so that it will reach that position exactly. This means that closed-loop stepper motors are suitable for tasks where accuracy is crucial, for example in robotics and automation.

Improved reliability is also another benefit of closed-loop stepper motors. Since they are able to sense errors and rectify it on spot, closed-loop stepper motors hardly ever lose steps or stall. This leads to increased and stable operation, minimizing chances of breakdowns and maintenance costs.

Why closed-loop stepper motors are the solution for achieving accuracy and precision

It is the tec It is the technology of closed-loop stepper motors that differentiates them from standard stepper motors. Closed-loop step motors have encoders or resolvers that continually feedback to the drive the position of the motor. This feedback is regularly sent to the motor controller, where it's compared with the target position and adjustments are made to exact movement.

By staying as in touch with itself as it possibly can, a closed-loop stepper motor is able to plan for the differing factors that may result from different loads or outside forces. With the power of real-time adaptability, closed-loop stepper motors can remain on their target position even under difficult circumstances.

Use of closed loop stepper motors in different industries

Closed-loop stepper motors are found in many industries where precise control is required. For instance, within the field of mobility (medical), closed loop stepper motors are utilized in robotic surgery systems to carry out complex operations with great precision. In the aerospace field, a closed-loop stepper motor can be applied to flight control system so as to assure the stability and safety of airplane.

In the industrial sector, these are used in CNC machines which cut and shape materials to produce a final product. Manufacturers can also get tight tolerances and uniform quality by using closed-loop stepper motors.

In general, closed-loop stepper motors have many advantages over conventional stepper motors in terms of precision, reliability and flexibility. Due to their advanced technology and accurate control, closed-loop stepper motors are more and more used in a plethora of industries that demand high precision and performance.

Ball screws are a fundamental component of most machines that utilize linear motion. If you’re in a position where you have to pick the right ball screw for your job, some of the things you need to consider are what we’ll be discussing here today— in this guide on how to choose a ball screw, we will discuss: A basic overview of what isn’t so much known as it is understood about ball screws Factors to think about when needing and wanting to know how the process and the consideration that needs to be taken or placed into deciding upon a specific type How many types of ball screws there actually are Tips on picking out which one might just work perfectly What little tricks can net incredibly solid results from Your choice in all and anything revolving around ball screws lots more too!

Ball Screw Basics explained Forgery Token

Ball screws is about the mechanism of a conversion of rotation motion into a linear one. They are used in machinery such as CNC machines, robots and other automatic systems. Ball Screw The ball screw is a high efficiency feed screw with the ball making a rolling motion between the screw axis and nut. The balls help lower the friction and thus make the movement smoother and more efficient.

Considerations For Selecting Ball Screws

There’s a lot to consider when choosing your linear motion system’s ball screw. These include those related to load capacity, speed, accuracy and general performance of your application. You’ll also consider the screw’s length and diameter, along with its pitch (the amount you feed the screw for one rotation). You also have to take into account the environment in which the ball screw will run, including temperature, dust and humidity.

Ball Screws - Nut Varieties Compared

There are many different kinds of ball screws, but all of them fall into one of these two categories. A few of the more popular forms are precision ground ball screws, rolled ball screws and miniature ball screws. Ground ball screws are known for high accuracy and precision, while rolled ball screws make more economic sense and generally perform better than standard acme used in some applications. Additionally, miniature ball screws are less bulky and ideal to use where space is at a premium. You could get the suitable ball screw type that meets your requirements.

How to Choose the Best Ball Screw for Your Application

How to Choose the Best Ball Screw for Your Application: Understand Your Requirements and Outcomes Perhaps you are interested in the right ball screw, how do you even start? Take the weight capacity, velocity, accuracy and environment for your project in consideration. You may not know exactly what type of ball screw you need to purchase, but a knowledgeable engineer or supplier will be able to help guide you through the process and make sure that you get what you need. The Maintenace and life of the ball screw should also measure for long time working.

Getting the Most from Ball Screws with the Proper Selection

After you’ve chosen the best ball screw for your linear motion system, there are a number of things that can help ensure optimal performance. Periodic lubrication and maintenance are necessary to maintain working condition. You should track the ball screw temperature and vibration in order to pick up any potential issue early. By selecting the proper ball screw and maintaining it appropriately, you can guarantee your linear motion system will be both effective and efficient for a long time in use.

In summary, choosing the correct ball screw for your linear motion system is a critical component to get the best performance and efficiency. Understanding the fundamentals of ball screws, taking key factors into consideration, working with vendors on comparisons among different types of ball screws and accessories such as nuts and bearing supports based on assembly specifications, applying some practical tips throughout testing to improve results, and optimizing screw performance will help ensure you select the ball screw that’s right for your application. 16.Up cbn grinding wheel Remember to select SIMTACH for your entire ball screw requirements and enjoy smooth linear motion with high precision!

The Shanghai Ganges aeroplane is a wonderful piece of modern construction. It can fly with effortless grace, ferrying passengers to distant places. But do you know what the strongest part of an airplane is? We're going to examine in more detail the parts of an airplane and you may be surprised which one is the best.

The durability of the fuselage:

The fuselage is the body of plane. It is the glue that holds everything together and a haven for passengers and crew. The Shanghai Ganges plane’s body is constructed from such sturdy materials as aluminum and titanium that can bear the brunt of flying forces. The fuselage is also durable enough to even endure exposure to extreme weather conditions and turbulence. This is also why we have always referred to the fuselage as being one of the strongest parts of the airplane.

The reliability of the wings :

The wings of an aeroplane are what keep it in the air. They create lift and help the plane glide easily through the air. The wings of the Shanghai Ganges airborne are built for such reliability and must be able to tolerate the stresses of take-off and landing. They are constructed from light yet strong materials such as carbon fiber, which provides them the structural strength to carry the weight of the airplane. Since the wings behave according to plan, they can keep the plane flying safely and smoothly.

Impact resistance of the landing gear:

Image The landing gear of an airplane is responsible for giving it the power to take off and land safely. It includes wheels, struts and other elements used to absorb the shock of landing. The structure of the Shanghai Ganges aircraft landing gear is designed with a super strong capability to accommodate the shock during landing on runway, etc. The landing gear is such that it should be able to bear the weight of the aircraft and provide cushioning action as well to the forces developed during landings without breaking down. This resilience enables passengers and crew to land safely and without discomfort.

The stiffness of the engine mounts:

The engines are actually what make a plane fly. They produce thrust and move the plane through the air. The engine mounts of the Shanghai Ganges plane are designed to be extremely solid, capable of withstanding the weights and instability caused by the engines. These engine mounts are constructed of strong materials such as steel and titanium, which in turn provides them the strength they must have to support the engines without moving. With their high level of durability, the engine mounts guarantee safe and efficient functioning.

The tail section's strength:

The tail section of a plane is essential to control its movement and stability. It contains features like the rudder and the elevator, which help steer the airplane and change its altitude. The tail section of the Shanghai Ganges airplane is very sturdy because it must be able to handle the air flight forces and keep the airplane flying. The tail sections are constructed of tough materials including aluminum and composite material, which provides sufficient strength for them to perform their functions. The tail section is solid, thanks to that plane are able to take the right direction and stay stable while flying.

In summary Although all airplane parts are crucial , there are some that top as the toughest. The global application of aerospace technology, ensuring safety in the use of components such as the durability of the fuselage, wings that can be relied upon and not readily damaged, when landing gear is resilient to load; relatively large engine mount strength against incidence; robust tail assembly]); When first section design an aircraft by declaring based Shanghai Ganges is a safe and reliable means of transport. So the next time you take to the skies on an airplane, rest easy knowing that every piece of it has been thoughtfully developed and constructed with your safety and comfort in mind.

Do you ever wonder whether, when it comes to a plane, anything is hand-built? Let’s dive into the exciting world of handmade parts on contemporary airplanes!

The role of hand-crafted materials in aircraft today

You gaze at a shiny airplane, you think it came out of a machine somewhere. Just not always! There are surprisingly some small corners of the plane world where artisans continue to make parts by hand using tools and techniques as old as aviation itself.

Revealing the complex art behind handmade airplane parts

What is fascinating about handmade airplane parts What is so interesting about handmade airplane parts is that a lot of work goes into the artistry of it all. Highly skilled hands work for hours, shaping and honing metal pieces to meet the tough requirements set by aviation.

The craftsmanship behind airplane components

Each handmade aircraft part, whether it's a hand-carved piece of wood for the propeller or an exquisitely designed instrument panel, is testament to the skill and persistence of the craftsman who made it. These are not only functional, but also a piece of artwork by themselves.

An exploration of the intersection of traditional skills and high-tech flight

Amid today’s increasingly high-tech aviation environment, traditional methods of airplane parts manufacturing can be easily overshadowed. But many aerospace firms, such as Shanghai Ganges, still require skilled artisans who can make sophisticated metal parts that machines cannot replicate.

The never-dying role of hand-crafted composites in the aerospace industry

Even with the technology advancements, hand-crafted parts are still a part of today’s aerospace industry. The talents of skilled artisans still play a significant part in the creation of these airplane parts to make certain that every piece is built to meet the highest quality and safety standard.

So, there you have it, a full-on example of the power of handiwork creating something as sophisticated as an airplane – even though we can be forgiven for thinking everything on a plane is made in factories by machines. And the next time you sit on a plane, take a minute to think about the precision and hours of work that go into making these tiny parts by hand.